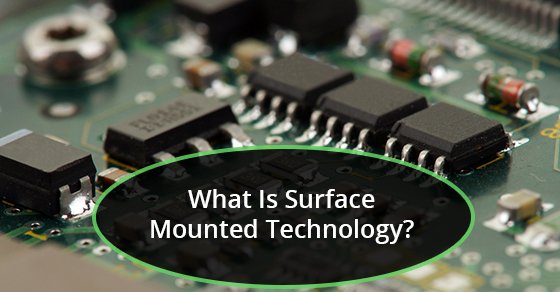

What Is Surface Mounted Technology?

Surface mounted technology, often referred to as surface-mount technology or SMT, is perhaps something you have heard of, but you aren’t exactly sure what it is. Rising to prevalence in the 1980s, SMT has become an increasingly popular method for producing electronic circuits. If you are producing printed circuit boards or are looking to have one produced for you, SMT may prove to be the perfect solution.

What is SMT?

Surface mounted technology is a way to produce electronic circuits that involves placing the components involved precisely onto the surface of a printed circuit board (PCB). Devices that are made in this manner are called surface-mount devices (SMD). SMT is now one of the go-to methods for PCB construction, replacing through-hole technology, which fit the board’s components with wire leads directed into the holes. If some of the components cannot handle surface mounting, as with heat-sinked power semiconductors and big transformers, both types of technologies can be used on the same PCB.

What Kind of Devices Are Made with SMT?

SMTs come in three categories which determines the type of device.

- Passive SMDs: These are capacitors or resistors that use standardized components like coils and crystals.

- Integrated circuits: Constructed from basic electronic parts, integrated circuits that are SMDs can vary depending on the type of connectivity required.

- Transistors and diodes: Typically found in a small plastic package, transistors and diodes use leads that form connections and actually touch the board.

Advantages and Disadvantages of SMT

Surface mounted technology comes with many benefits because of the way it is designed and manufactured. Furthermore, SMT uses a lower mass of components that provides better shock and vibration resistance. In general, the advantages of SMT outweigh the disadvantages, which is why it is the preferred method of producing PCBs.

| Advantages of SMT | Disadvantages of SMT |

|---|---|

| Automated production and soldering saves time | Repairing the board can be difficult because of the small component size |

| Reduced cost compared to other PCB production methods | Through-hole construction may be required for large or high-power parts |

| Components can be placed on either side of the board | Components that need to be connected and disconnected frequently can be impossible for SMT |

| Can better handle vibrations, exceptional performance in shaky conditions | |

| Components are smaller and denser |

Surface mounted technology is a favourite for printed circuit board producers. For more information about SMT and SMDs, please contact us.